Shop Premium Used Evaporative Condensers | Industrial Cooling Solutions

- Specifications

- FAQs

- ←

- →

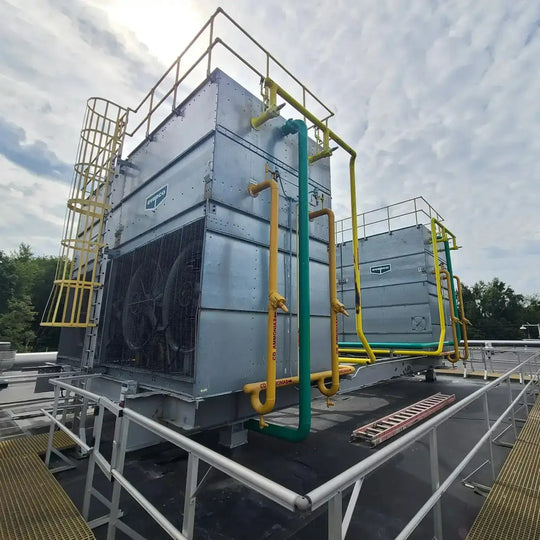

Evaporative condensers are efficient and cost-effective cooling systems that utilize the process of evaporation to remove heat from an enclosed space or system. In other words, an evaporative condenser uses evaporated water to cool down the surrounding environment. They are commonly used in industrial applications and commercial operations to cool air and other substances.

You'll find a refrigeration condenser in applications like food and beverage manufacturing, cold storage, and other industries where industrial refrigeration is necessary. This type of equipment is often used to keep products at the right temperature in order to ensure their quality and longevity.

As mentioned, an evaporative condenser is an effective, low-cost solution for air conditioning and refrigeration systems. It's used in large commercial applications and can be found in industrial facilities, supermarkets, and other large-scale operations. Just like the name implies, these condensers employ an evaporative cooling process to condense the refrigerant vapor and release the heat of compression. These condensers use the cooling effect of evaporation to improve the heat rejection process.

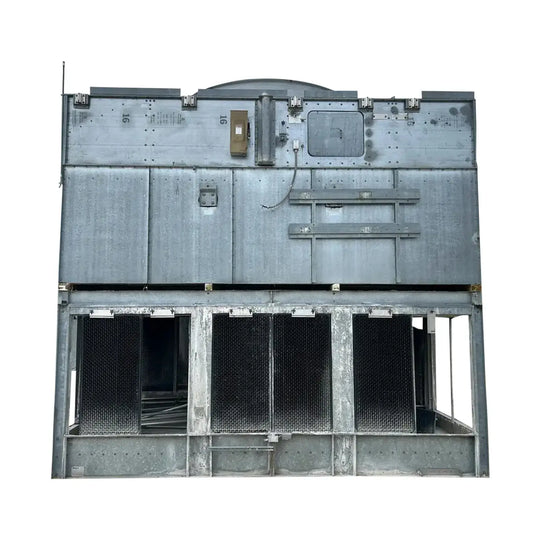

An evaporator condenser consists of a large container or tank divided into two sections. The top of the unit is filled with water. Spray water is misted onto the condensing coil located at the bottom of the cooling tower. As the water evaporates, it cools the coils, which contain the refrigerant vapor. This process of evaporative cooling causes the refrigerant to condense, releasing the heat of compression. The cooled refrigerant liquid is then collected in the bottom section of the evaporator condenser in tubes, where it's ready to be used in the vapor refrigeration system again.

Induced-draft cooling towers have fans that are typically mounted on top of the cooling tower to pull air through the fill media. Additionally, forced-draft cooling towers employ blowers located at the base of the air inlet face to push air through the cooling tower. Centrifugal fan units are capable of overcoming reasonable amounts of external static pressure, making them suitable for both indoor and outdoor installations. Axial fan units are more efficient as they require approximately half the fan motor horsepower of comparably sized centrifugal fan models.

Industrial evaporative condensers are a type of heat exchanger that uses evaporation for heat transfer from the refrigerant. The condenser transfers excess heat from the refrigerant to the outside air, which is then exhausted. Air-cooled condensers are the most common type used in HVAC systems. They use a fan to draw in outside air and pass it over the condenser coil.

Water-cooled condensers are similar to air-cooled condensers, but instead of using air to cool the refrigerant, they use spray water. Genemco offers a wide selection of evaporator equipment from Evapco, Vilter, BAC, Imeco, and all other leading manufacturers. You can also shop for used condensers to ensure you stay within your budget.

Yes. The evaporative condenser design typically requires a continuous supply of water flow to operate efficiently. However, the machine itself is designed to use minimal water. This is all thanks to the closed-loop system that recirculates water throughout the system. So, you can rest assured that spray water is not wasted. It undergoes a purification process and is reused. The recirculating water system is what makes it exceptional quality equipment.

The evaporative process utilizes water flow through a closed-loop system to cool an area. Meanwhile, air conditioning utilizes air along with refrigerants. This refrigerant gas can be converted from a gas to a liquid and back to gas again. An AC typically uses more energy and power to operate, so it comes at a much higher cost when it comes to both operation and installation. Getting a used evaporative condenser from Genemco results in higher cost savings.

Just like any other mechanical equipment, evaporative condensers require regular maintenance to ensure optimal operation and longevity. You'll want to schedule periodic inspections as well as clean the condenser coils, the water distribution system, and the drift eliminators to prevent scale deposits or buildup and maintain efficient heat transfer. It's also important to monitor the water chemistry and treat it appropriately. This will help ensure you prevent corrosion in the coils and prevent any other biological growth in the equipment itself.

Top Sellers

View all